Build Track's

Jim Bridger's Hawken rifle,

right hand, 1-1/8" tapered octagon barrel

|

|

Build Track's

Jim Bridger's Hawken Rifle kit,

1-1/8" tapered octagon 36" barrel,

traditional iron, or fancy brass trim, maple stock

Track's very best Jim Bridger's Hawken Rifle parts were selected by the well respected gunmaker, Michael Hayes of Park Rapids, MN, who built the fine rifle with tapered octagon barrel, shown above. Stocked in curly maple, this nice stock has fine tiger stripe figure, and is strikingly handsome. Trimmed with traditional iron furniture, this gentleman's Hawken rifle is profusely engraved. The snail bolster of the breech is hooked to the tang. Push the two barrel wedge keys open, withdraw the ramrod, and the barrel will lift and unhook from the tang, instantly, without tools, for easy cleaning after a day of shooting. The wedge keys have a capture slot with pin installed, so they can never be completely removed from the stock or lost. The mountain man appreciated ease of maintenance as much as we do, today. The engraved long tang hooked breech plug is fitted with two tang bolts that engage the trigger plate, another correct Hawken feature. The trigger plate is very long, extending through the wrist, accepting two tang bolts from above. The long trigger plate, long tang, and two bolts, form a steel reinforced wrist, making the Hawken the strongest Plains rifle in this critical area. When viewed from above and below the tapered lock panels are clearly visible. The lock panels taper widest at the front, opposite from early long rifles which are widest at the rear. This architectural detail, influenced by English rifle makers, is pre-shaped in our Jim Bridger's pre-carved Hawken halfstock. A single lock bolt retains the lock, recessed into a tear drop shaped iron sideplate inlay. The classic beaver tail cheekpiece is a standard feature on half-stock Hawken rifles. The cheek is angled to recoil away from your face, an ingenious feature found on better rifles. Our semi-buckhorn rear sight, and silver blade front sight are both correct features.

Track's Jim Bridger's Hawken stock is available cut for a 1-1/8" tapered octagon barrel, to build a moderate weight rifle. The strong 1-1/8" breech accepts our 3/4-16 plug. Tapered octagon barrels taper to 1" at the muzzle over a length of 36", making a handy offhand and hunting rifle. We can install our Jim Bridger's Hawken hooked breech plug, at extra cost.

We offer Green Mountain and Rice barrels in tapered octagon profiles for this rifle. Not recommended as a first project, assembly of a Hawken rifle requires the skilled use of a drill press, file fitting of the lock plate to the plug, and the installation of an under rib. If you are comfortable with these tasks, you will have no difficulty with this kit. Our gunsmith can install the rib, sights, forward pipes, and plug, at extra cost.

Green Mountain barrels are 1-1/8" tapered octagon, 36" length, threaded for breech plug. Available in ., .54 caliber only in a round ball twist. Green Mountain muzzle loading rifle barrels are machined from high quality American made bar stock, A.I.S.I. 1137 modified, stress relieved, annealed, certified rifle barrel quality steel. All barrels are drilled from solid stock, reamed to a high degree of smoothness, then optically checked for straightness. Very close tolerances are maintained. Diameters vary less than .0002" within any bore.

Cut Rifling Specifications:- Each barrel has eight lands and grooves.

- Grooves cut .010 to .012" deep, depending on caliber.

- Twist is 1 turn in 70 inches for .54 caliber.

Rice Muzzle Loading Rifle Barrels cost a bit more than other barrels, due to the extra attention given to the bore and surfaces. Made in the USA, by L.C. & Liston Rice all bores are reamed, rifled, and "ball burnished" to a mirror finish, with a more uniform bore diameter than can be achieved with reaming alone. Match quality, no break-in period, no hand lapping is required. This barrel will shoot accurately from the very first shot.

Cut Rifling Specifications:- Cut rifled, each bore has 7 lands and grooves.

- Grooves are cut .016" deep, with square rifling.

- Twist is 1 turn in 66 inches, for .50, .54, .58, or, .62 caliber round ball.

- Rice barrels do not require lapping or extensive shooting to break-in.

- Crown is 60 degree lathe cut and polished.

Rice Muzzle Loading Rifle Barrels are set between centers and milled octagonal, insuring a centered bore, concentric with the exterior, with no "run-out". Each barrel is stress relieved in an atmosphere controlled electric furnace, to eliminate work hardening or barrel warp, and to dampen harmonic vibrations or barrel whip. After the rifling has been cut, each bore is "ball burnished". A carbide bore-sizing die is pulled through the barrel, to insure bore dimension uniformity, eliminating any tight or loose spots inside the barrel. This critical procedure leaves the top of the lands smooth and polished, equaling the traditional lead lapping procedure. Rice barrels are Match grade quality, with bench rest capability. Rice barrels do not require lapping or extensive shooting to break-in. Rice Muzzle Loading Rifle Barrels are premium quality barrels in every sense! A small maker's trade mark, and caliber mark, is stamped near the breech, on the bottom of each barrel. Rice Muzzle Loading Rifle Barrels are threaded to an inside depth of .500". We can quickly install a breech plug, underlugs, and sights, at small extra cost. See our gunsmithing service options. Allow three to seven days shop time, when you choose optional labor.

Perfected and refined by Michael Hayes our Jim Bridger's Hawken rifle stock is precision machine inlet for any 1-1/8" tapered octagon barrel, our Jim Bridger Hawken lock, 1-1/8" slant-faced breech plug & tang, double set triggers, entry pipe, sideplate inlay, slotted oval wedge key inlays, and toeplate. The hole for 7/16" rod is drilled full depth. Trigger reach is 13-3/4", drop is 4" from the line of sights, butt end is 5 x 1-1/4", cut for our wax cast Jim Bridger's Hawken buttplate. The forend is about 15" length.

Our wax cast Jim Bridger's Hawken furniture: buttplate, sideplate, toeplate, inlay escutcheons, triggerguard, forend cap, and 7/16" ramrod pipes, are offered in wax cast brass, or traditional iron (wax cast steel). The sideplate is the later smaller style. Rib is drawn steel. Correct unplated screws and pins are included. Front sight has a copper dovetail base, with nickel silver blade. The rear sight is a semi-buckhorn, or optional 5 step adjustable Hawken rear sight. Our gunsmith can install the sights, after fitting the breech plug, at small extra cost, with prompt delivery.

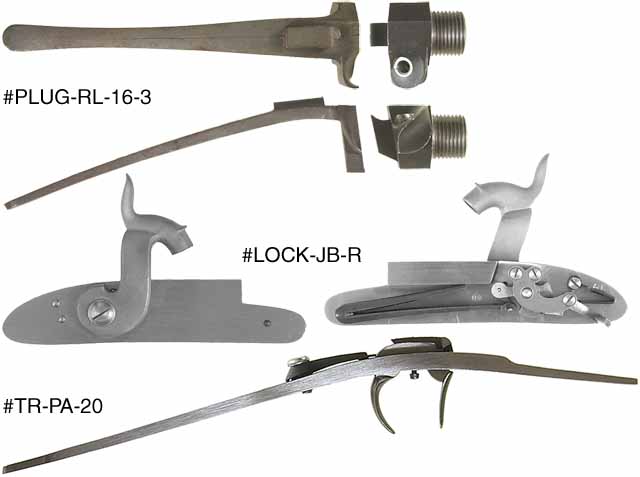

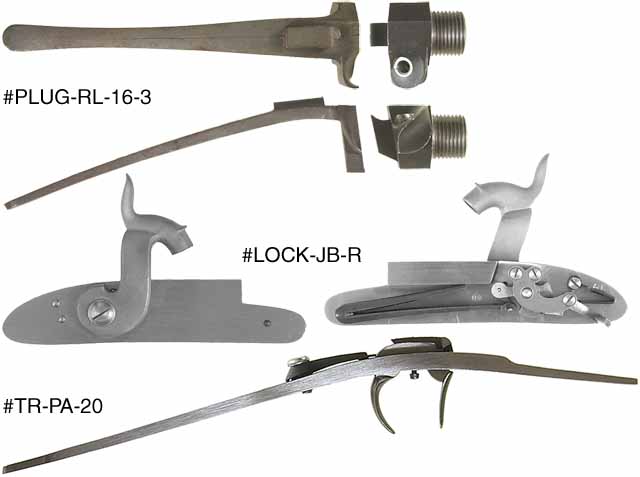

#PLUG-JB-18-3: This 1-1/8" Hawken plug was designed by Green River Rifle Works. The tang may be bent cold. The short .500" thread journal allows a strong engagement and a direct drilled ignition hole. Pre-inlet into our Jim Bridger's Hawken stock, since these castings virtually snap fit together. After fitting the tang to the plug, it is best to temporarily join the two pieces with glue or solder and inlet the entire barrel assembly as one part. Apply anti-seize compound to threads, before installation. We recommend Birchwood Casey's Choke Tube Lube. Our gunsmith can install this breech plug, at small extra cost.

#LOCK-JB-R: Designed by Ron Long, Denver, this famous lock was used by Green River Rifle Works, of Roosevelt, Utah, on their famous Hawken rifle. This lock emulates locks made by the Hawken brothers of Saint Louis, circa 1840-1850. Wax castings are nicely finished, tempered, assembled, and signed by R. E. Davis. Smooth internal parts, polished critical points, turned bearing surfaces, and a heavy duty mainspring give this lock a crisp action. Fitted with a fly, this lock works well with Hawken style double set triggers.

#TR-PA-20: The famous lock maker, Ron Long, Denver, designed this trigger for the Hawken rifle. Made by R. E. Davis, each trigger bears his (D) touch-mark. This double lever trigger has the required backlash to allow the lock to be cocked and fired, while the trigger is set or unset. Trigger release is easily adjusted, using the trigger adjustment screw. For best trigger geometry, place the trigger adjustment screw directly under the sear of the lock.

Gunsmithing Labor: Our gunsmith can install the plug (LABOR-BP), front and rear sights (2 LABOR-DS), mount the under rib using four screws (4 LABOR-DT), and solder the two ramrod pipes to milled notches in the rib (2 LABOR-RP), at small extra cost, with prompt delivery.

#LABOR-BP: Our gunsmith will install your breech plug, in your barrel, with the front face of the breech plug tightly sealed against the inside shoulder of the breech thread, and the barrel maker's name indexed to the bottom flat. Threads are lubricated with Birchwood Casey's Choke Tube Lube anti-seize, so the plug may be removed, even after decades of use. Never remove a breech plug, unless you have a compelling reason. The plug is never removed for cleaning, and should only be removed by a skilled gunsmith, who has the correct tools to avoid marking your polished and finished barrel and plug.

#LABOR-DS: When you buy the sight from us, we will remove any burrs, gates, or parting lines, and hand fit the sight to the dovetail slot, ready for you to finish and use. Many of our rear sights are cast with an oversize base, to allow these to fill oversize slots. It is wise to allow us to trim these to a standard size, before installation in a new barrel. We must install the breech plug before installing sights, rib, or pipes.

Front sight slots are centered 1.5" from muzzle, unless your clearly specify another location. Do not embed special instructions within lengthy text of a letter. Place special instructions immediately after your written order for that item, or in the comment field of our on-line order form.

Rear sight slots are centered 8.5" from the breech end of the barrel (not including plug), unless your clearly specify another location. Do not embed special instructions within lengthy text of a letter. Place special instructions immediately after your written order for that item, or in the comment field of our on-line order form.

#LABOR-DT: We drill and tap blind holes, usually 5-40, drill, counter-bore and mount the rib. Rifles usually require four (4) screws. We require fitting the breech plug before performing this operation.

#LABOR-RP: We mill a flat on each rod pipe, and a matching flat notch in the rib. After "tinning" both flats with solder, we clamp the pipe, heat the joint, and cause the two solder coated surfaces to be joined, known as sweat soldering. We require fitting the breech plug and mounting the rib before performing this operation.

#LABOR-RSHA: Our gunsmith will mill a dovetail for your Hawken adjustable rear sight, using a milling machine and dovetail cutter and hand fit the sight with riser. This labor will replace one of the #LABOR-DS for the rear sight installation.

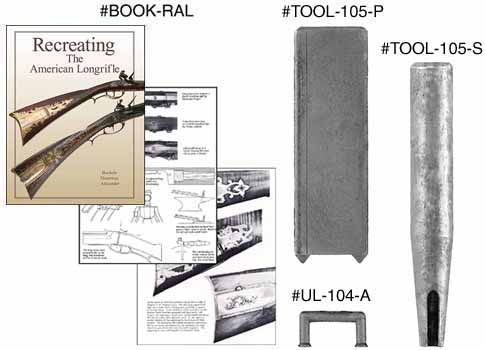

If you have never built a rifle from scratch, we recommend the book Recreating the American Longrifle. While not specific to Hawken rifles, this book explains many gun making techniques in detail. The late William Buchele was recognized as a true master longrifle maker. But his greatest contribution to muzzle loading must be this book. He shares the step by step details of his craft. His work has been enhanced by the editors. This book does not assume that the reader is an expert stock maker, but begins with illustrated explanations of the basic concepts. Buchele shows several alternate approaches to most tasks. Newly revised fifth edition. Full scale plans include a carved longrifle and fullstock pistol. Over 250 photos and drawings within the 176 pages, 8-1/2 x 11" format, soft cover.

Discussed in Recreating the American Longrifle, Track's underlug staples are authentic, stronger, easier to install, and they remove less metal than dovetail lugs. Not suitable for thin walled barrels, staples work well for keys, pins, or for supporting a sling swivel.

#TOOL-105-P: Align our double punch with a centerline drawn on the bottom flat of your octagon barrel. Strike it to prick punch the exact spacing for our staples. Very handy for quick and accurate staple location. Lay your key or pin in the open staple. Measure the staple leg extending above your key or pin. Drill your holes exactly that depth. Select a drill bit to match the staple foot diameter (about 7/64"). We recommend using a drill press. Set a quill stop to avoid drilling too deep. Hole depth determines key slot thickness.

#TOOL-105-S: Insert one end of our staple into your hole, and seat it with a light hammer blow. Place the semi-circular slotted end of this tool around the staple's seated end. Strike it with firm blows, to stake the staple permanently in place. Seat the opposite end, and stake it. Malleable staples allow bending. Stake one end securely, before attempting to seat the other end. Straighten after staking.

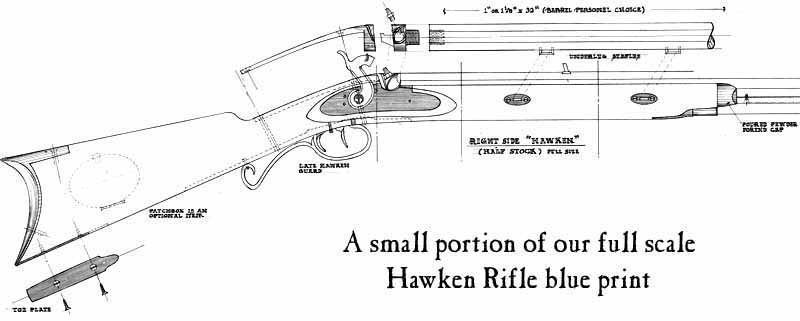

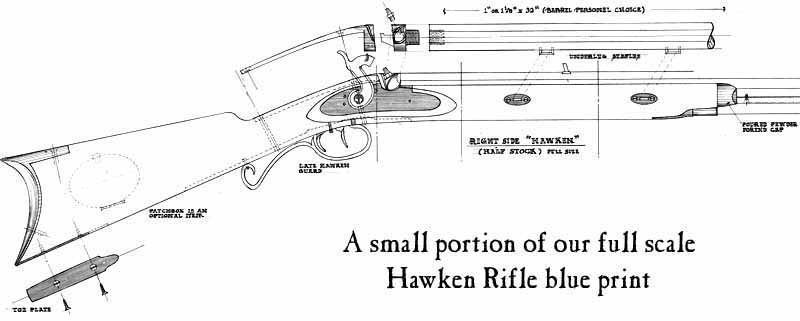

This large blueprint details construction of both the classic late Kit Carson's Hawken halfstock rifle, and the earlier fullstock Hawken rifle. Both guns are shown on the same plans, in separate views, to illustrate the similarities. These plans show you the inside details to help you understand how to build your own Hawken rifle.

Typically 40 hours of skilled labor is required to build a Hawken rifle. Use of a drill press in recommended. A skilled mentor, as always, can be a invaluable aid in building any rifle.

We strongly recommend that you order our new catalog, which describes this kit in great detail, explains the options, and shows most individual parts and in exact full size photographs.

Gun building is fun! Click ADD TO CART, and send your order, for same day shipment.

Track of the Wolf, Inc.

18308 Joplin St NW

Elk River, MN 55330-1773

Copyright ©

2025 Track of the Wolf, Inc.